Midwest Moments: Quince and Apple

It's rare these days when I take a vacation without it somehow revolving around the world of cheese. When we initially bought tickets to the Midwest, it was fully supposed to be a vacation around visiting friends and family. I guess my friends and family circle has changed because I quickly filled our time with seeing producers. We had no intentions of going to Madison but after working with Matt and Quince and Apple at the Fancy Food Show, I knew I needed to see what was going on in Wisconsin. I've talked about Quince and Apple before. My love for their products runs deep. It fits a profile of things I love. Small batches, delicate flavors that compliment cheese versus masking, and a core belief in creating a better community through good food. I needed to see it all up close and personal.

Like many artisan products, Quince and Apple began with a hobby. Matt grew up making preserves with his mother and as he got older he continued to make them as gifts for friends or just fun experiments in the kitchen. After years of working in kitchens and for other people, he decided it was time to make a go of it for himself. I'm sure it was a difficult conversation with his wife, Clare, but fortunately she was on board and willing to help him pursue his dreams. Now, what started out as a two person team 8 years ago has turned in to a fully functioning business with multiple employees and a proper production facility near the heart of downtown Madison.

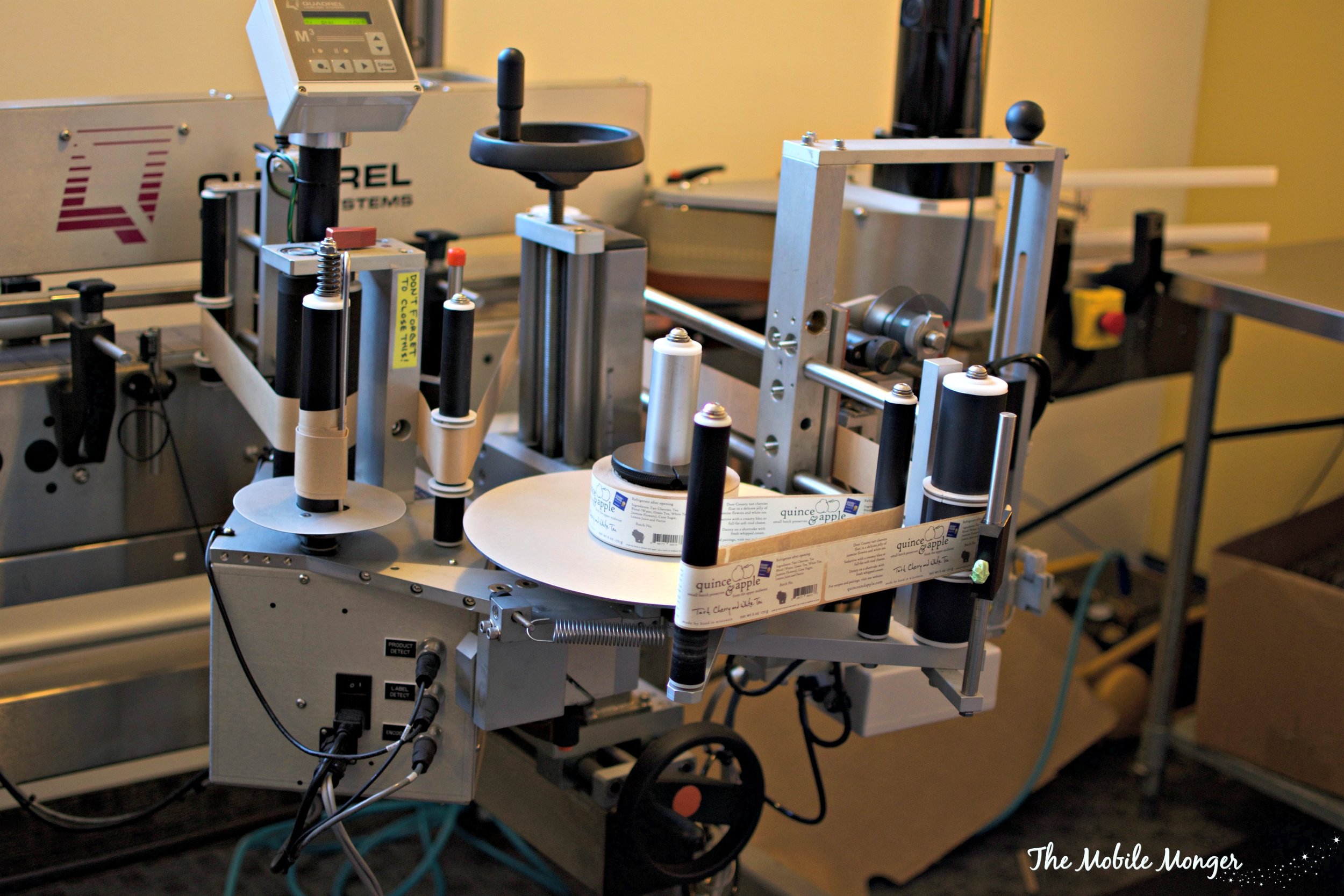

Sounds like a perfect success story, right? Here's where things are done a little differently around Q&A. A lot of companies at this level of growth would start thinking about outsourcing their production to start saving money and going bigger. Q&A has made the commitment to continue producing small batches by hand to ensure that the same level of quality is going in the product. This, in turn, has many different results. It ensures a continued commitment to their employees by securing work. It adds employment in the area because their consistent growth will require more shifts and batches to be made. It also keeps the quality in the hands of the employees because each batch is constantly being touched, assessed, and sometimes even labeled by hand. As more companies move towards automation, this is huge. Automation is great for many things but sometimes there are just times where a human touch is needed. Yes, things can still get missed but every batch is directly tied to a team of employees so issues can be dealt with in a timely manner. In the world of taste, a hands on approach is a great way to go, in my opinion.

All of this doesn't even mention the fact that Q&A's core values as a company revolve around respect, integrity, feminism, and locality as much as possible. These values build better business and can prove that good business can also mean good values.

All of that being said, lets look at how things are made!

Remember that small batch business I was talking about? This is it right here. 4 pots for each batch because they have found that this formulation allows for the quality to remain in tact while also not putting too much work on to the maker. Here they are making the Shallot and Red Wine. I kept smelling shallots on my clothes all day but I can't say I was upset about it in the least.

A pallet of sugar was delivered while I was there and though that's the most sugar I've ever seen in my life, I know that it pales in comparison to many jam and preserve companies. Q&A specifically uses a lower amount of sugar so the fruit is able to fully express it's flavor without being overshadowed by sweetness. This makes all their products a dream for pairing with foods. I was not there to see them filling the jars but they do all of that by hand too.(Check out their website to see some cool pictures of that process!) The personal touch even comes down to the labeling machine because the person that created that specific batch that's being labeled, was the one that made the batch the day before. Things don't just get passed on to the next person down the line. The sense of ownership is there throughout the entire process.

All of their shipping and storage is done in the same place as the product is being made so since they have a small space for inventory, they make the products fresh to order. This means that it might take some time to fulfill a big order but it's guaranteed not to have just been sitting in a warehouse for an undetermined amount of time.

I feel fortunate that I have so many great relationships with producers that they invite me in to see what they are doing. They inspire me and I want everyone to know their story and to taste the beautiful and creative products that they are making.

In a world that can feel like no one is paying attention or cares, these are the moments I treasure the most because I know that it's just not true. People DO care and there are so many out there just trying to make the world a better place and good food is always a great beginning.